Choose Your Material

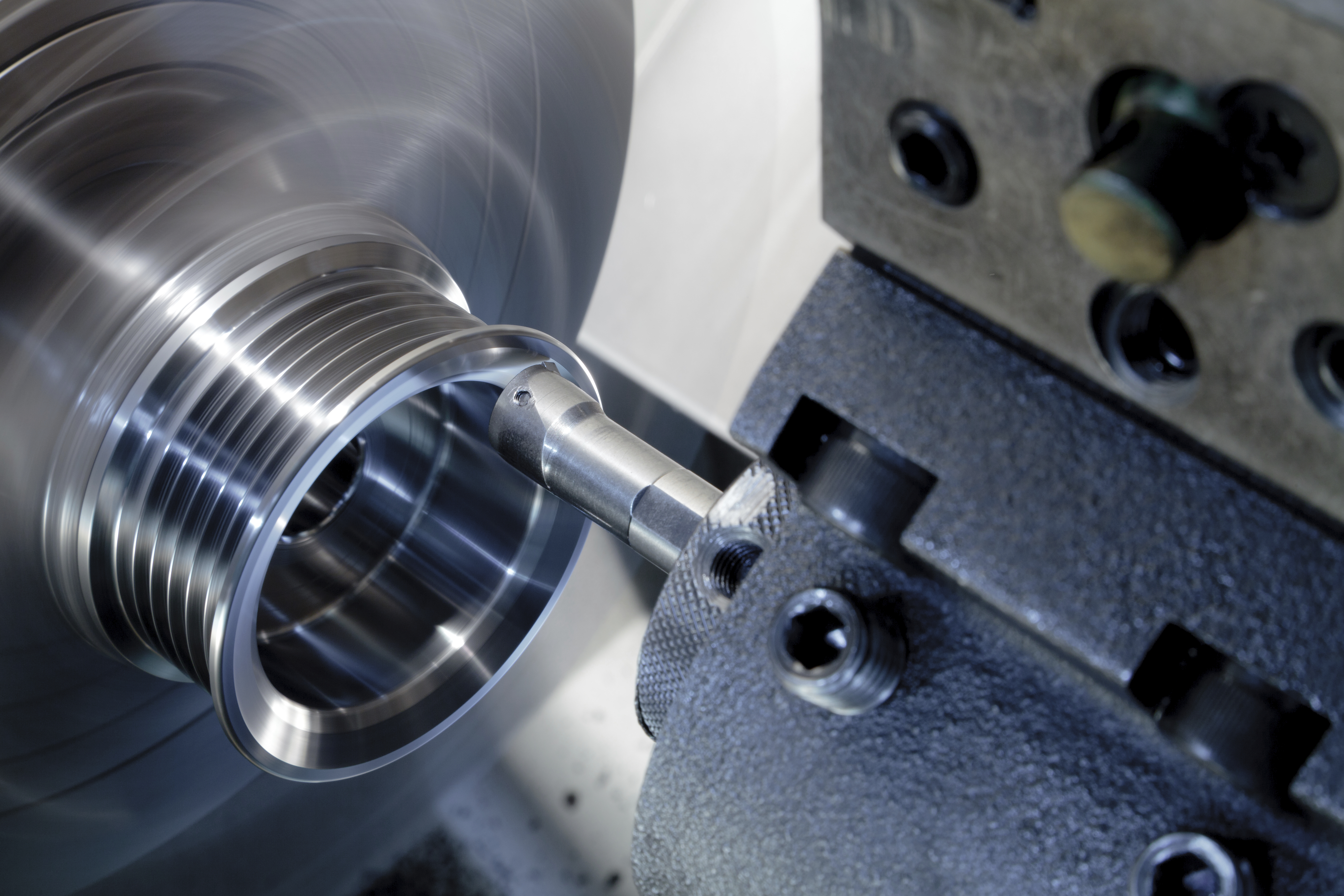

CNC (Mill & Lathe)

CNC (Mill & Lathe)

Additive Manufacturing LLC offers 3rd, 4th and even 5th axis machining services for both milling and turning. We can quickly produce parts, models, fixtures, and tools for short-run and high-volume quantities using every commercially available material.

Tech Data Sheets

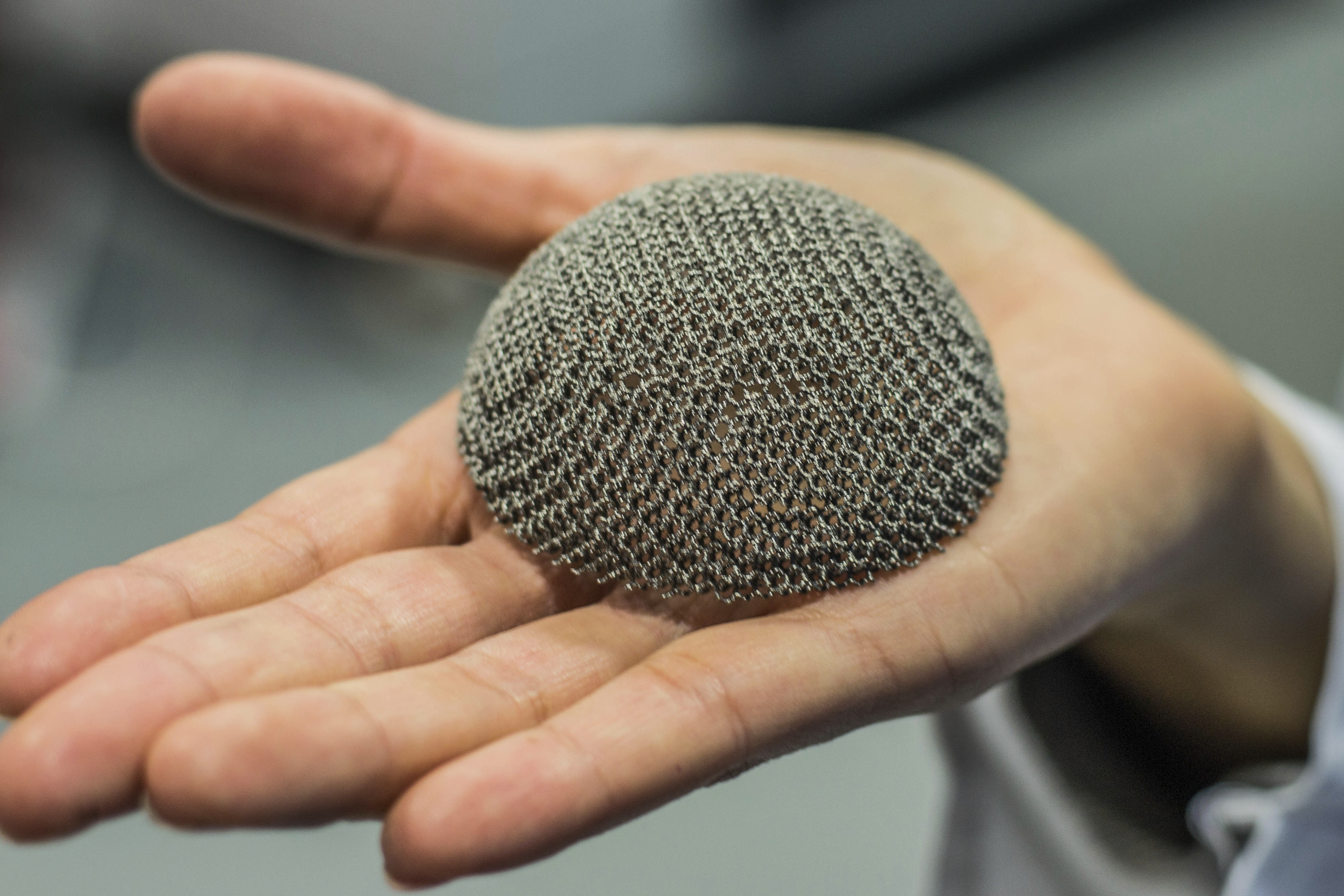

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS)

DMLS is the leading "additive" process for creating complex metal parts that are often difficult to machine or investment cast. Multiple materials available. Our largest build chamber size is 15" x 15" x 15", and we now offer hi-res builds using the new Trumpf machine.

Tech Data Sheets

Electron Beam Melting (EBM)

Electron Beam Melting (EBM)

EBM material is currently limited to Ti-6AI-4V and Cobalt Chrome. New alloys will be available soon.

Tech Data Sheets

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM)

FDM extrudes production-grade thermoplastic material to produce prototypes and additive manufacturing applications. Completed parts are robust, extremely high in accuracy, and have crisp details. A broad range of materials are available. Our largest build tray size is 36" x 24" x 36".

Tech Data Sheets

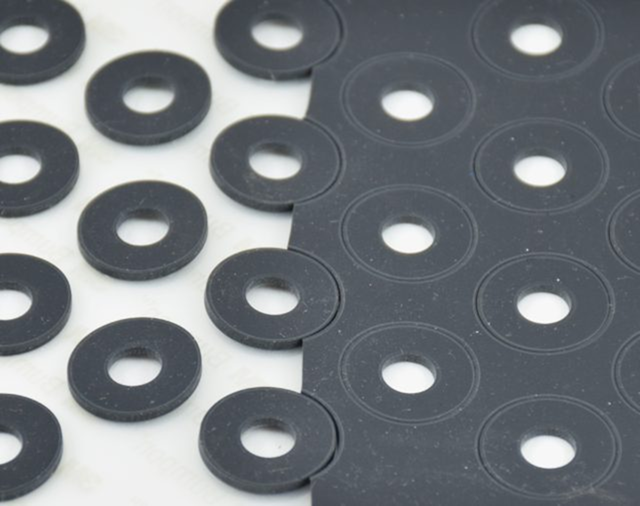

Injection Molding / Compression Molding / Extrusion Molding

Injection Molding / Compression Molding / Extrusion Molding

Injection Molding: All commercially available plastics, silicones and rubber.

Compression Molding: Natural Rubber, Nitrille Rubber, Styrene Butadience Rubber, Fluorocarbon Rubber, Butyl Rubber Isobutylene Isoprene Rubber, Silicone, Ethlyene-proyene Diene Monmer, Chlorprene Rubber, & Fluorosilicone.

Extrusion Molding: All commercially available plastics and rubber, and 6000 series aluminum.

Tech Data Sheets

Laser & Die Cuttting

Laser & Die Cuttting

MATERIALS:

- Neoprene

- Silicone

- Poron

- Buna

- EPDM

- Neoprene

- Buna ‘N’

- Viton

- Fishpaper

- Recycled

- Cellulose

- Compressed

- Vulcanized

- EMI / RFI Shielding

- Conductive

- Thermal Management

- Polyurethane

- Polyethylene

- PVC

- Poymide

- Mylar

- Teflon

- Acrylic

- Rubber

- UL-rated materials

OUR EXPERTISE:

Our passion for success is evident in the quality of parts we produce and the competitive price at which we produce them. We support our customers in every facet of new product development. It our job and our desire to provide continuous support and communicating with our customers, and we will provide dozens of product samples until the job is complete. We are resilient in our desire to be successful so your product can be equally successful.

Technical Build Specifications for Die & Laser Cutting:

STANDARD LEAD TIME: 1 – 2 weeks STANDARD ACCURACY (Die Cutting): Tolerances to +/- .005” STANDARD ACUURACY (Laser Cutting): Tolerances to +/- .002” STANDARDY ACCURACY (Slitting): Tolerances to +/- .010” MATERIAL THICKNESS: Up to .250” PART SIZE: Material specific IDEAL APPLICATIONS Consumer electronics, personalized electronics, new product development, high-volume production applications, refurbished electronics requirements.Tech Data Sheets

Multi Jet Fusion

Multi Jet Fusion

Multi Jet Fusion technology produces economical parts, especially at higher part volumes, that have the appearance of injection mold quality. Because parts are built continuously with infrared lamps fusing an entire layer in a single pass as opposed to a single laser, build lines typically seen on SLS parts are much less noticeable. This unique build style also achieves excellent strength in the Z axis and allows for significantly faster throughput and repeatability.

Tech Data Sheets

Polyjet

Polyjet

Polyjet is perfect for reproducing prototype models while achieving details as fine as 0.0006”. Polyjet parts do not require support structure, and are best suited for accurate and detailed applications. Multiple materials are available including rigid, rubber, clear and dual-blend materials for overmolding applications.

Tech Data Sheets

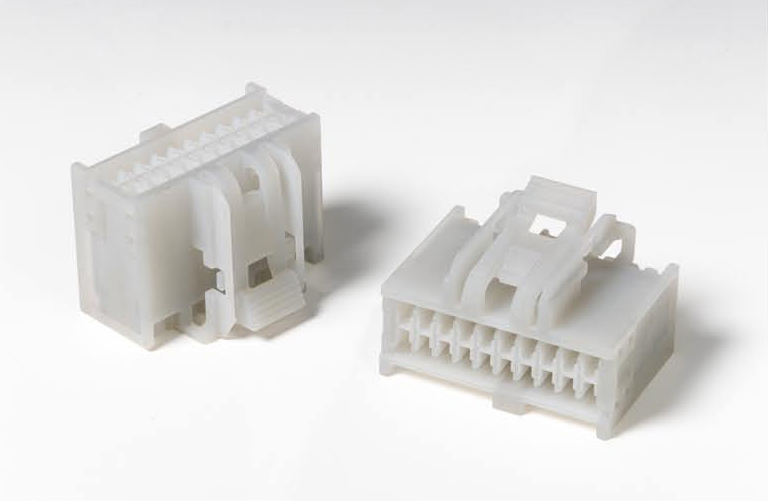

RTV Molding / Urethane Castings

RTV Molding / Urethane Castings

Room Temperature Vulcanizing (RTV) is a short-run, soft tooling (silicone mold) molding process used to produce anywhere from 5 to 300+ parts. Materials available closely simulate injection-molded plastic, rubber and silicone.

Tech Data Sheets

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a rapid prototyping and manufacturing process that sinters (fuses) a variety of nylon-based materials for quick-turn models or for short-run production.

Tech Data Sheets

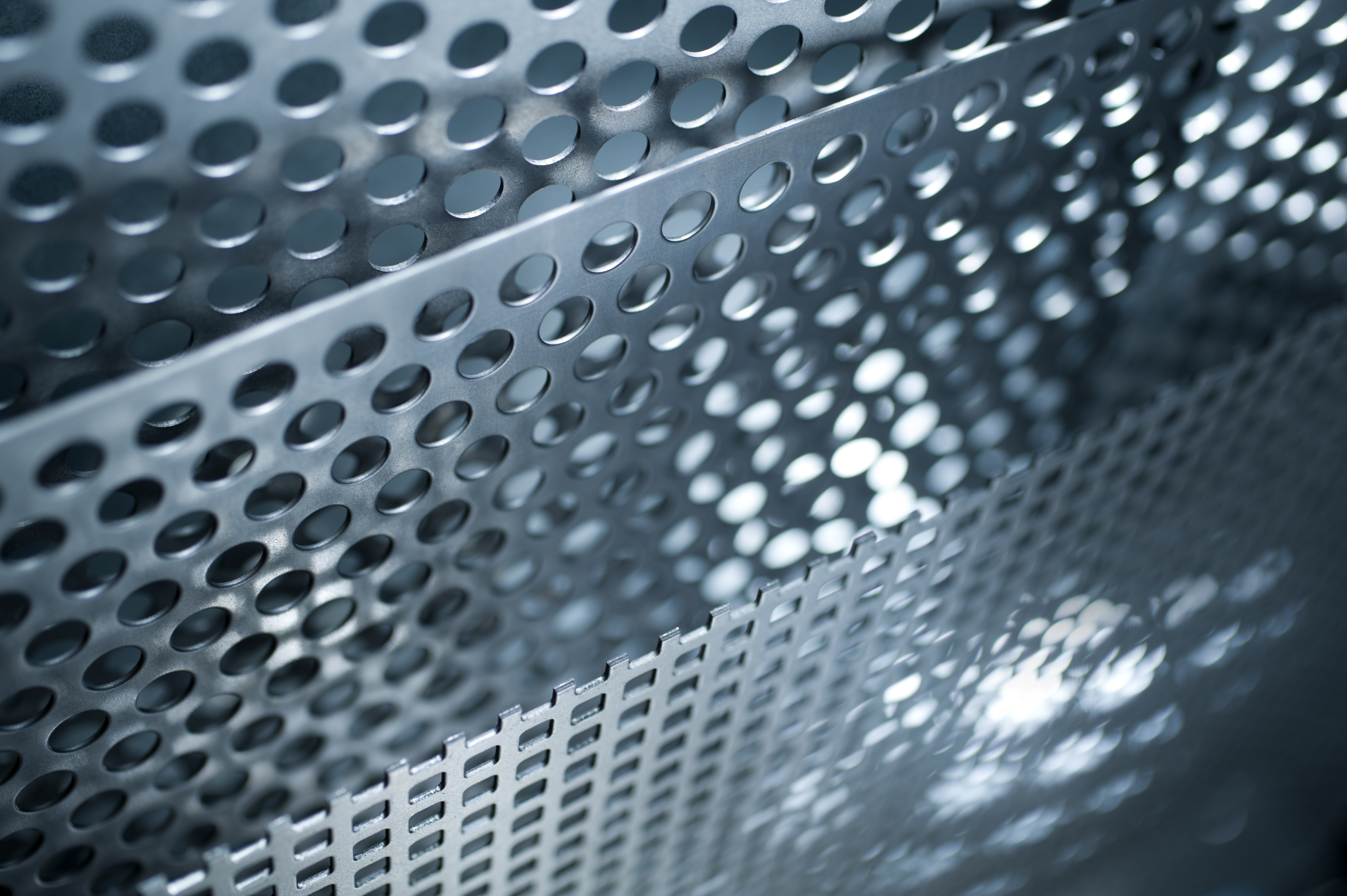

Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

Aluminum, Beryllium Copper, Brass, Carbon Steel, Nickel Alloys, Phosphor Bronze, Stainless Steel.

Tech Data Sheets

Stereolithography (SLA)

Stereolithography (SLA)

Parts made from SLA can quickly be used to make cavities in silicone molds, serve as patterns for investment or plaster castings, and can also be easily painted for form and fit studies.

Tech Data Sheets