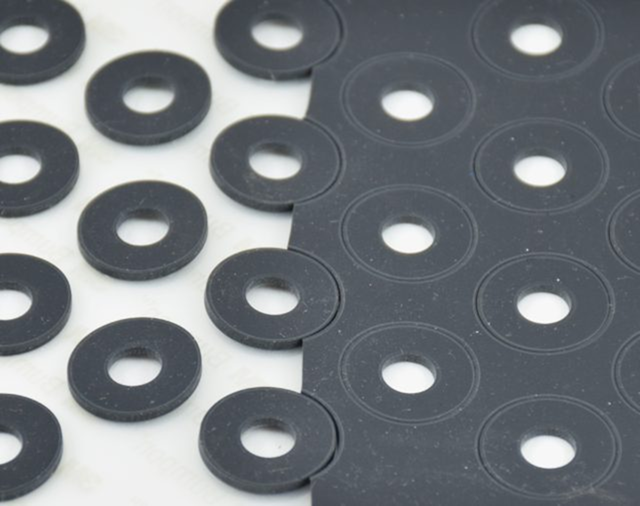

Laser & Die Cuttting

MATERIALS:

- Neoprene

- Silicone

- Poron

- Buna

- EPDM

- Neoprene

- Buna ‘N’

- Viton

- Fishpaper

- Recycled

- Cellulose

- Compressed

- Vulcanized

- EMI / RFI Shielding

- Conductive

- Thermal Management

- Polyurethane

- Polyethylene

- PVC

- Poymide

- Mylar

- Teflon

- Acrylic

- Rubber

- UL-rated materials

OUR EXPERTISE:

Our passion for success is evident in the quality of parts we produce and the competitive price at which we produce them. We support our customers in every facet of new product development. It our job and our desire to provide continuous support and communicating with our customers, and we will provide dozens of product samples until the job is complete. We are resilient in our desire to be successful so your product can be equally successful.