- Home

- Services

- Services

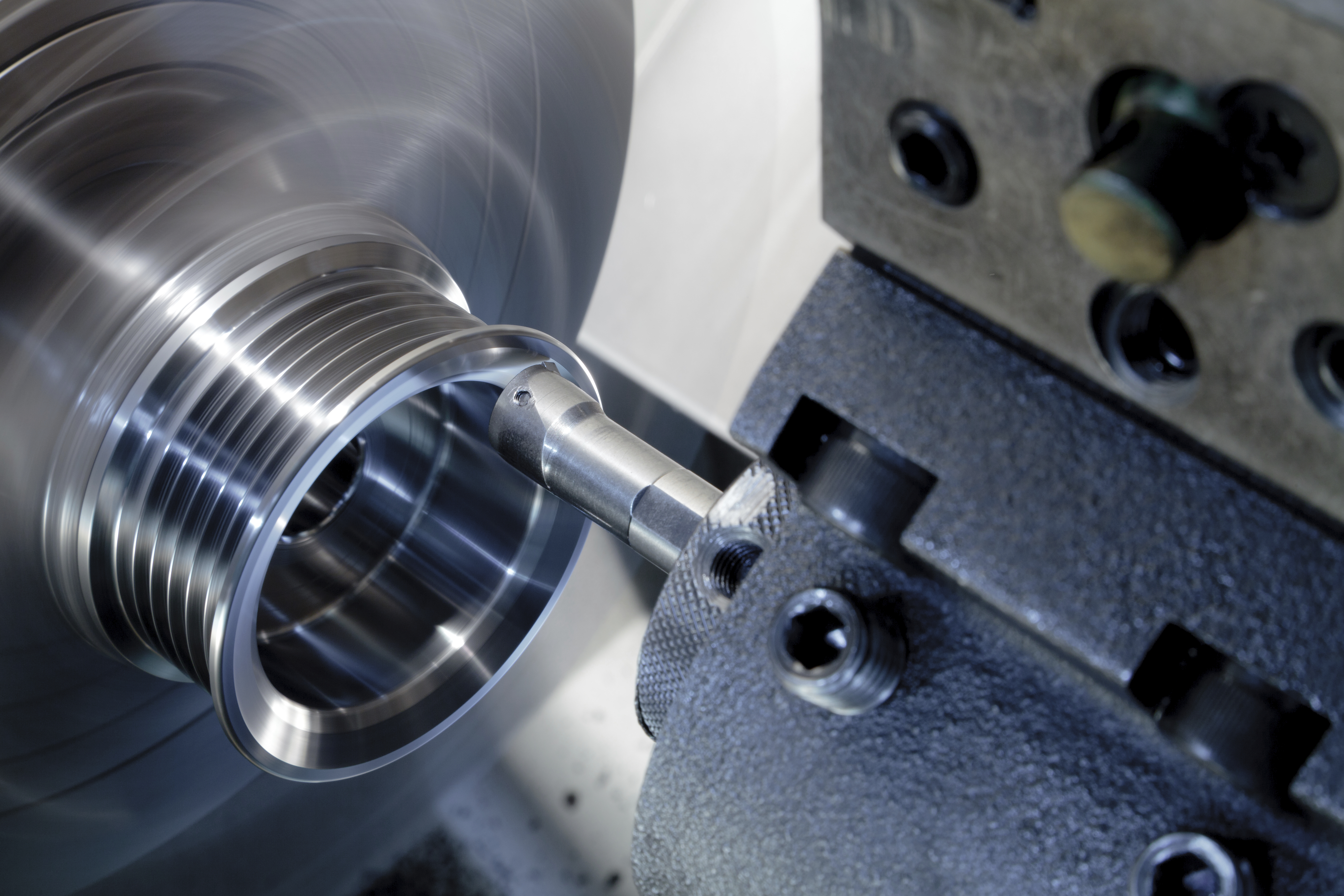

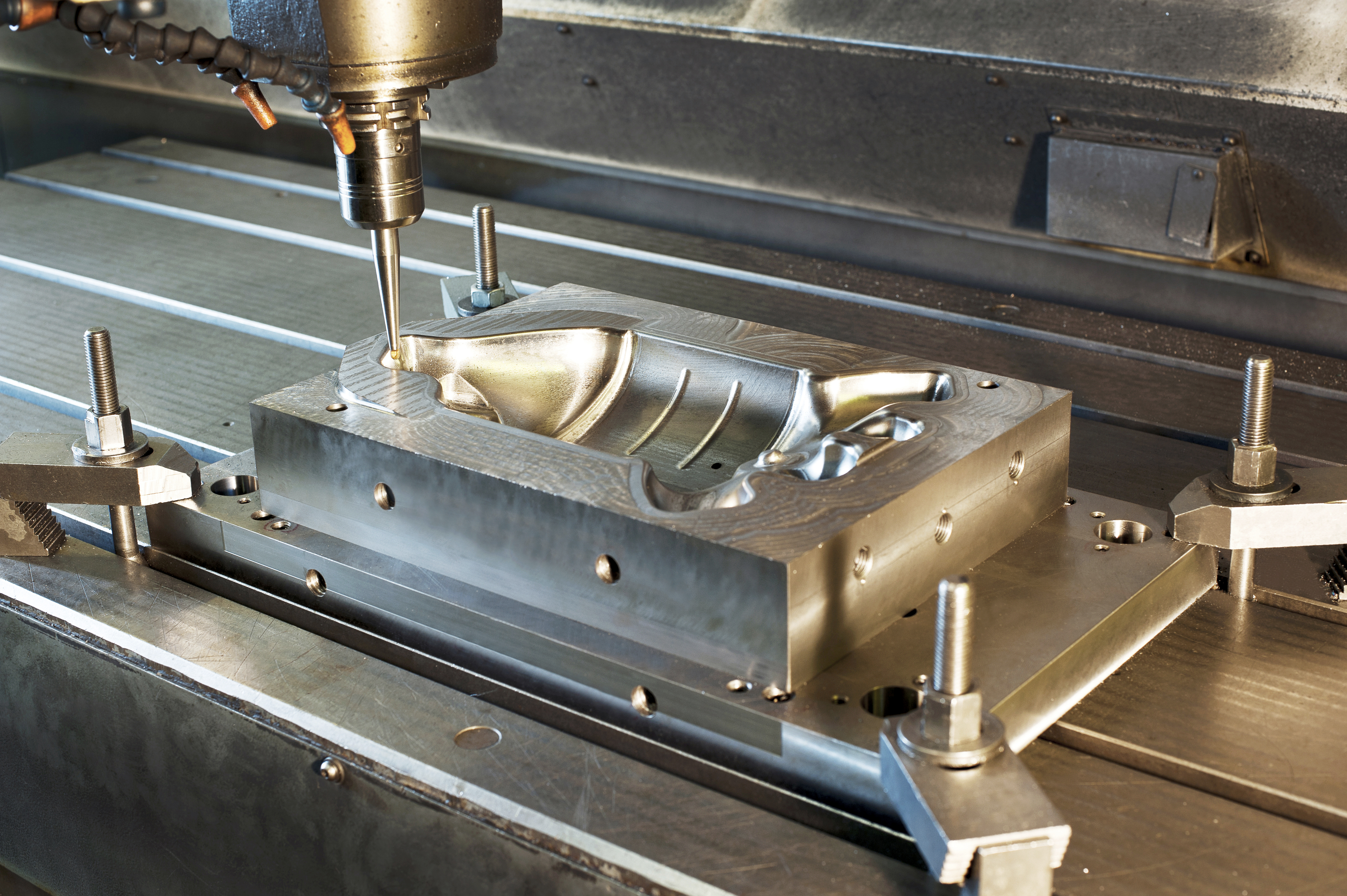

- CNC (Mill & Lathe)

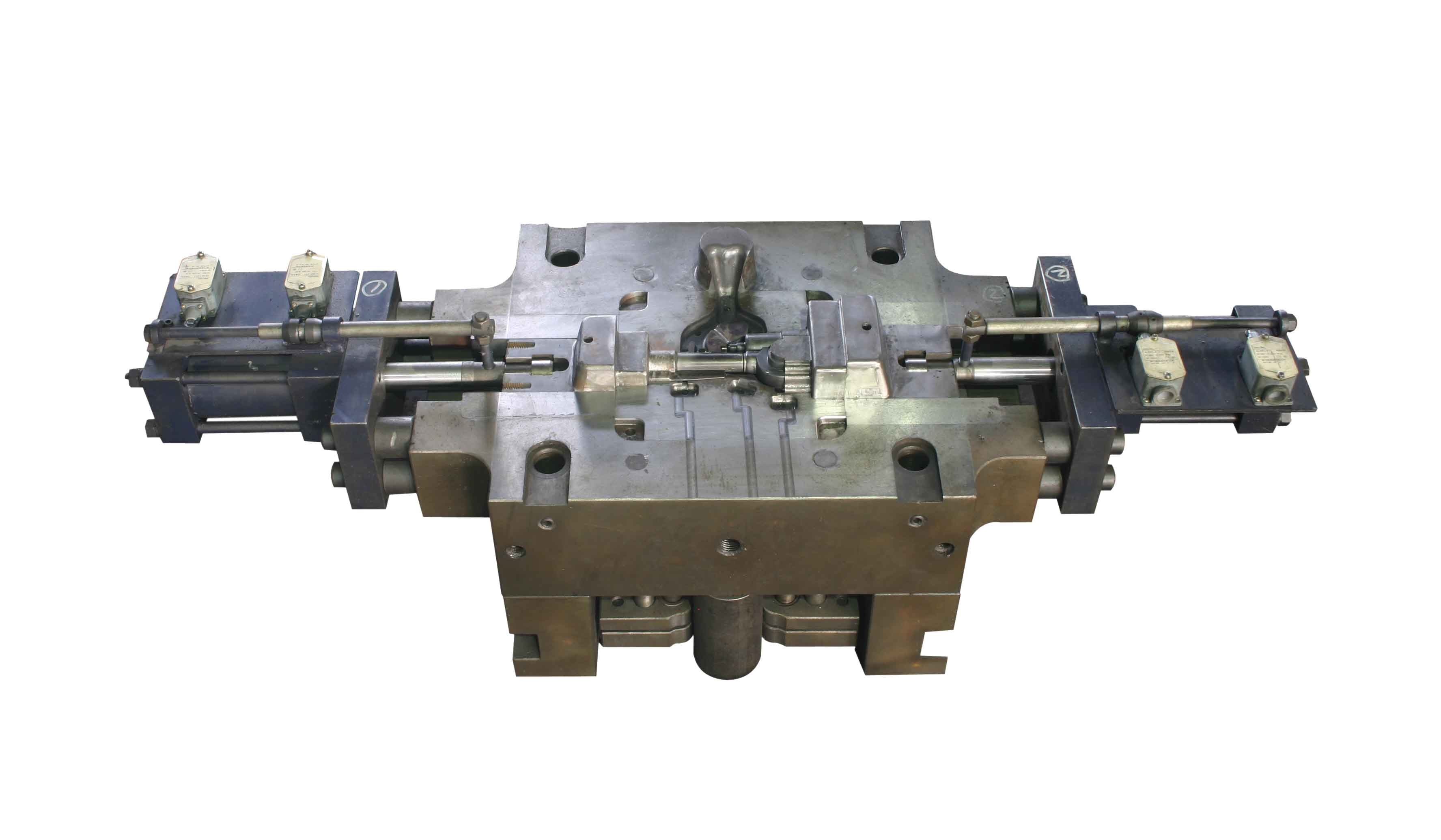

- Die Casting

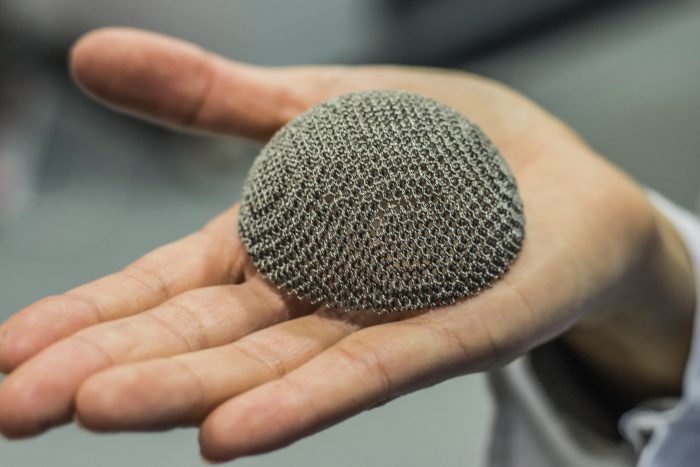

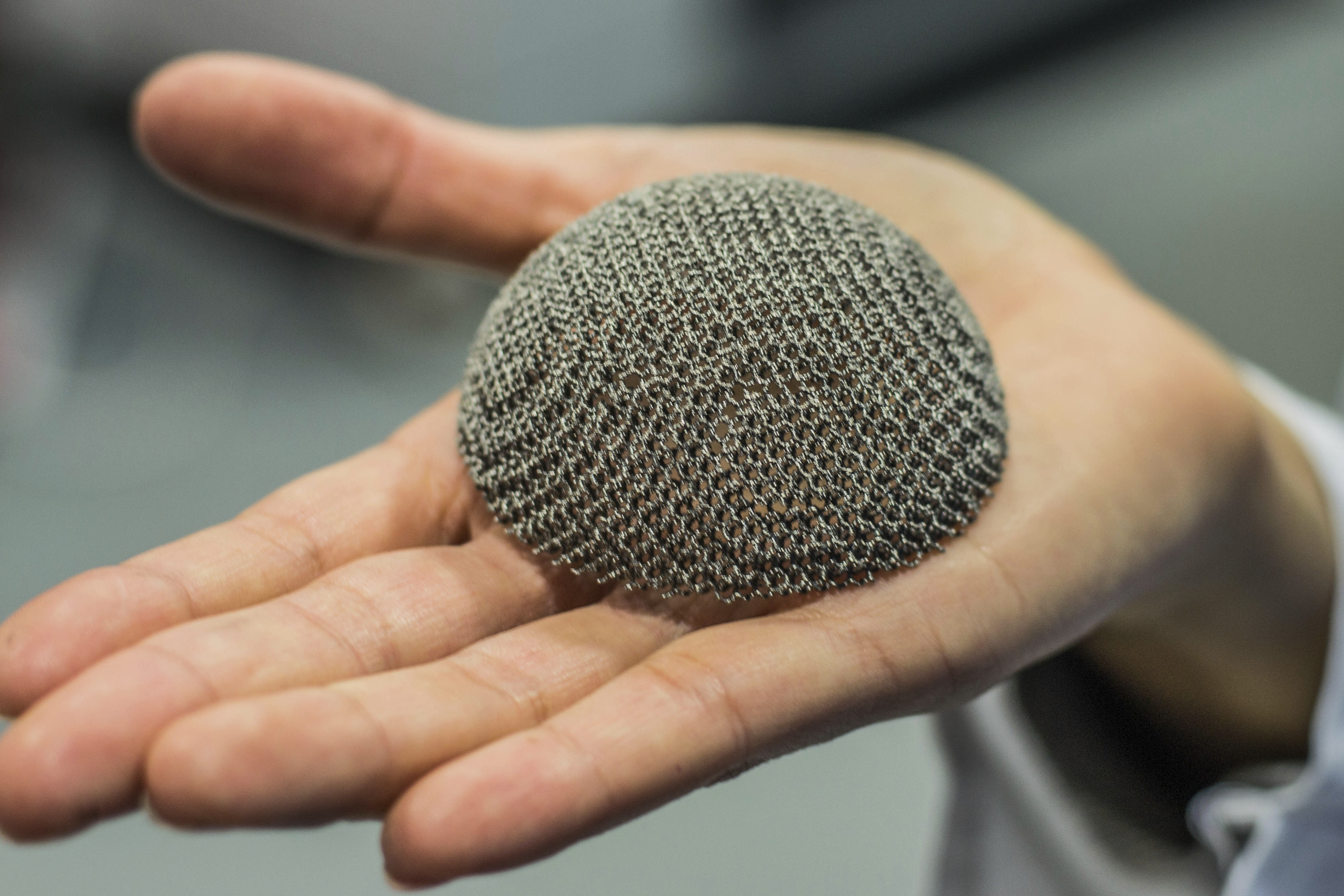

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Fused Deposition Modeling (FDM)

- Injection Molding

- Investment Castings / Plaster Castings

- Multi Jet Fusion

- Polyjet

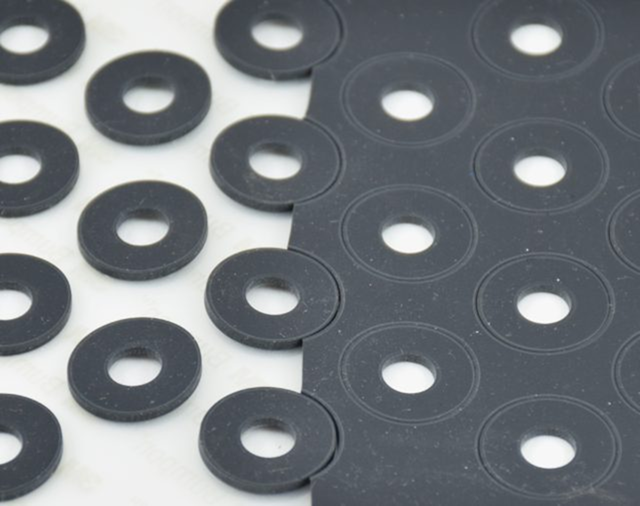

- RTV Molding/Urethane Castings

- Selective Laser Sintering (SLS)

- Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

- Stereolithography (SLA)

- Materials

- Materials

- CNC (Mill & Lathe)

- Die Casting

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Fused Deposition Modeling (FDM)

- Injection Molding

- Investment Castings / Plaster Castings

- Multi Jet Fusion

- Polyjet

- RTV Molding/Urethane Castings

- Selective Laser Sintering (SLS)

- Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

- Stereolithography (SLA)

- Post Processes

- Post Processes

- CNC (Mill & Lathe)

- Die Casting

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Fused Deposition Modeling (FDM)

- Injection Molding

- Investment Castings / Plaster Castings

- Multi Jet Fusion

- Polyjet

- RTV Molding/Urethane Castings

- Selective Laser Sintering (SLS)

- Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

- Stereolithography (SLA)

- Contact Us

ISO 9001:2015 CERTIFIED ITAR CERTIFIED