Resources

-

Tech Sheets

-

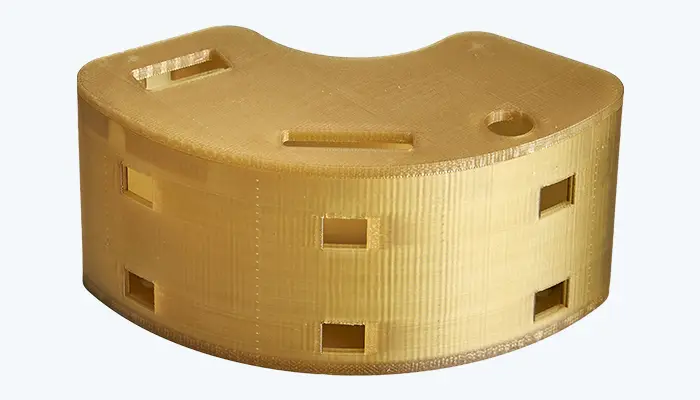

SLS parts are among the most difficult to finish due to the thick layer resolution needed.

- Vapor Honing

- Water Sealing

- Painting (with generous layers of primer)

- Drilling

- Tapping

- Insert and Hardware Installation

Post Processes

SLS parts are among the most difficult to finish due to the thick layer resolution needed.

- Vapor Honing

- Water Sealing

- Painting (with generous layers of primer)

- Drilling

- Tapping

- Insert and Hardware Installation

Technical Info

Parts can be printed in a single piece as large as 36” x 24” x 36”

Tolerances are + 0.020” for the first inch or + 0.005” inch / inch whichever is greater

Part Infill options: Solid or Hollow

Wall thickness should be designed at 0.059”

Minimum feature size 0.039”

Minimum hole size is 0.039”

Lettering should be designed at 0.35” tall and wide for raised fonts

Tech Sheets

Other Services:

No services foundGet in Touch with Us

Reach Out for Inquiries, Assistance, and More

Please contact us if you have any questions, comments or require

Need a Quote?

Features of our quoting system

Upload Files Directly

Just simply create an account, and upload your 3D files.

24 Hour Access

It can be hard to get things done over the phone, just use our system any time of day.

Digital Quotes

Upload your files, and we will send you a personalized quote.

Experienced Manufacturers

You can trust the brand Additive Manufacturing LLC

Best Prices

We offer competitive pricing to any client, small or large.

Register for your quote