Resources

-

Materials

Array -

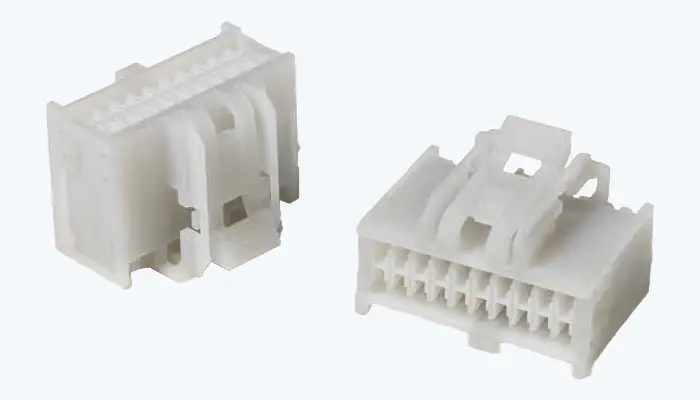

The post process requirements are specific to the material used. Rigid plastic compression molded parts can be finish machined, etched and painted. Most softer silicone material are neither finish machinable nor paintable, but soft urethane can be painted.

Plastics

- Finish CNC

- Etched

- Painted

- Drilled

Elastomers not including silicone

- Painting

Post Processes

The post process requirements are specific to the material used. Rigid plastic compression molded parts can be finish machined, etched and painted. Most softer silicone material are neither finish machinable nor paintable, but soft urethane can be painted.

Plastics

- Finish CNC

- Etched

- Painted

- Drilled

Elastomers not including silicone

- Painting

Technical Info

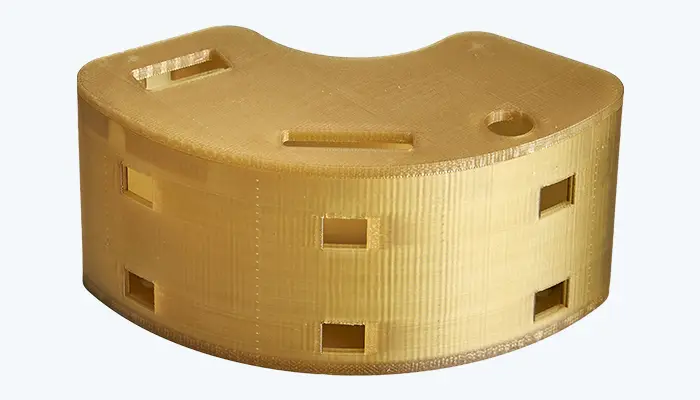

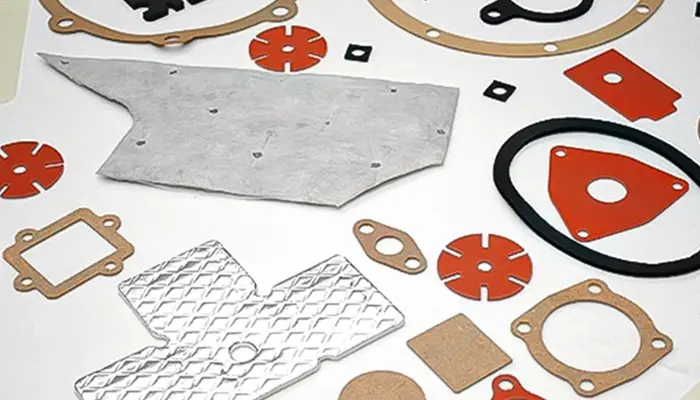

Material range includes thermosets, thermoplastics, elastomers, and natural rubbers

Part tolerances for compression molded rubber parts range from + 0.004” – 0.090”, varying by the length and thickness of the part

Corner radii should be designed greater than 0.050” although 0.010” can be achieved with the correct design

We recommend avoiding any undercuts

Circularity tolerances range from 0.006” – 0.008”

The minimum diameter of a hole should be 0.050”, and the height of a hole should not be more than twice its diameter

Minimum wall thickness should be 0.060” – .118”, depending on the material being used

Materials

- Silicone (varying durometers)

- Optical-Grade Silicone

- Medical-Grade Silicone

- Fluorosilicone

- Urethane

- High-density Polyethylene (HDPE)

- Epoxy

- Melamine

- Polytetrafluoroethylene (PTFE)

- Polyphenylene Sulfide (PPS)

- Neoprene

- Butyl

- Polypropylene

- Polystyrene

- UHMWPE

- EPDM

- Viton

- Nitrile

- Nylon

- Butyl

- Phenolics

- PEEK

- Nylon

Get in Touch with Us

Reach Out for Inquiries, Assistance, and More

Please contact us if you have any questions, comments or require

Need a Quote?

Features of our quoting system

Upload Files Directly

Just simply create an account, and upload your 3D files.

24 Hour Access

It can be hard to get things done over the phone, just use our system any time of day.

Digital Quotes

Upload your files, and we will send you a personalized quote.

Experienced Manufacturers

You can trust the brand Additive Manufacturing LLC

Best Prices

We offer competitive pricing to any client, small or large.

Register for your quote