Investment Castings / Plaster Castings

Brief Overview

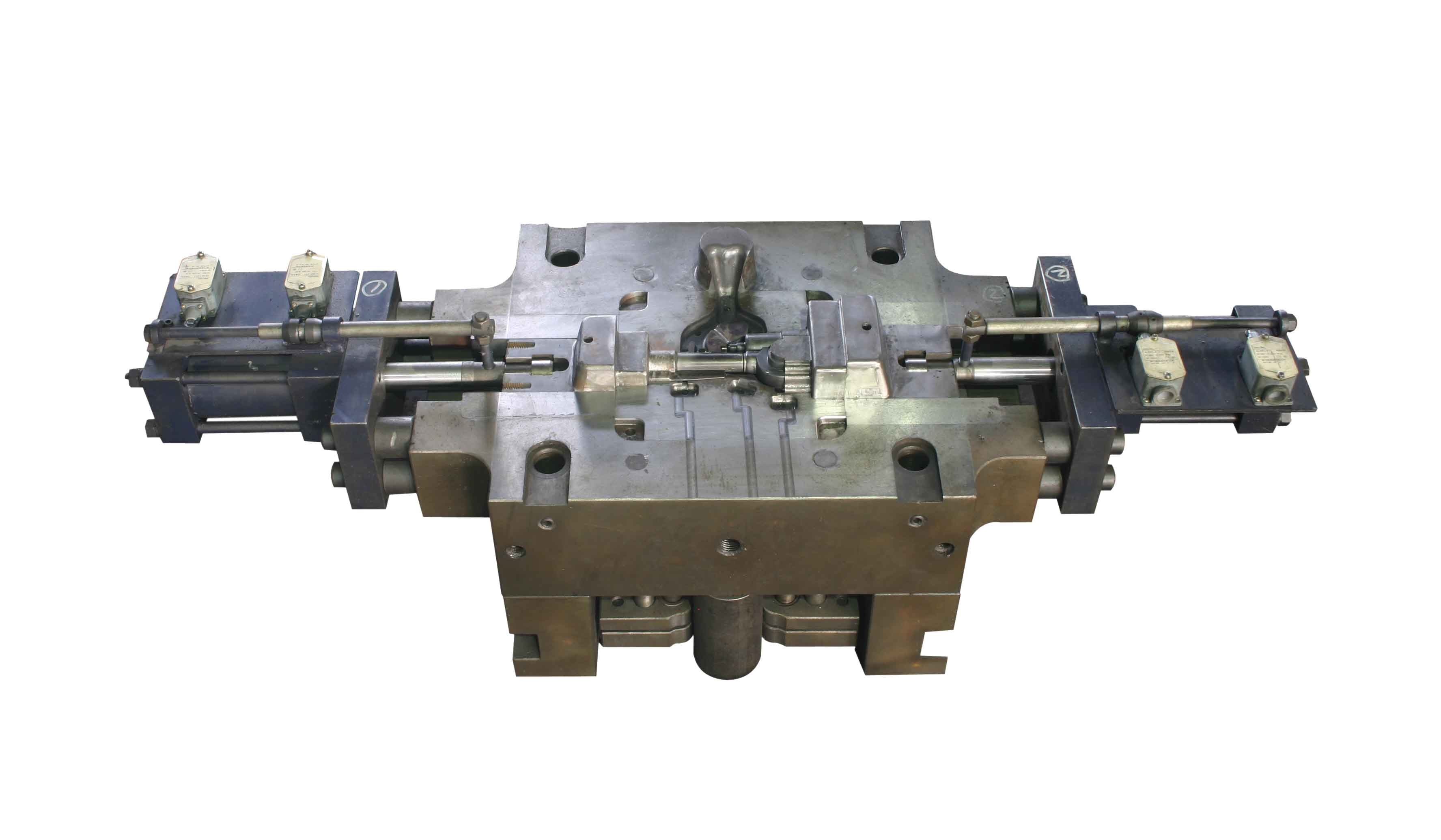

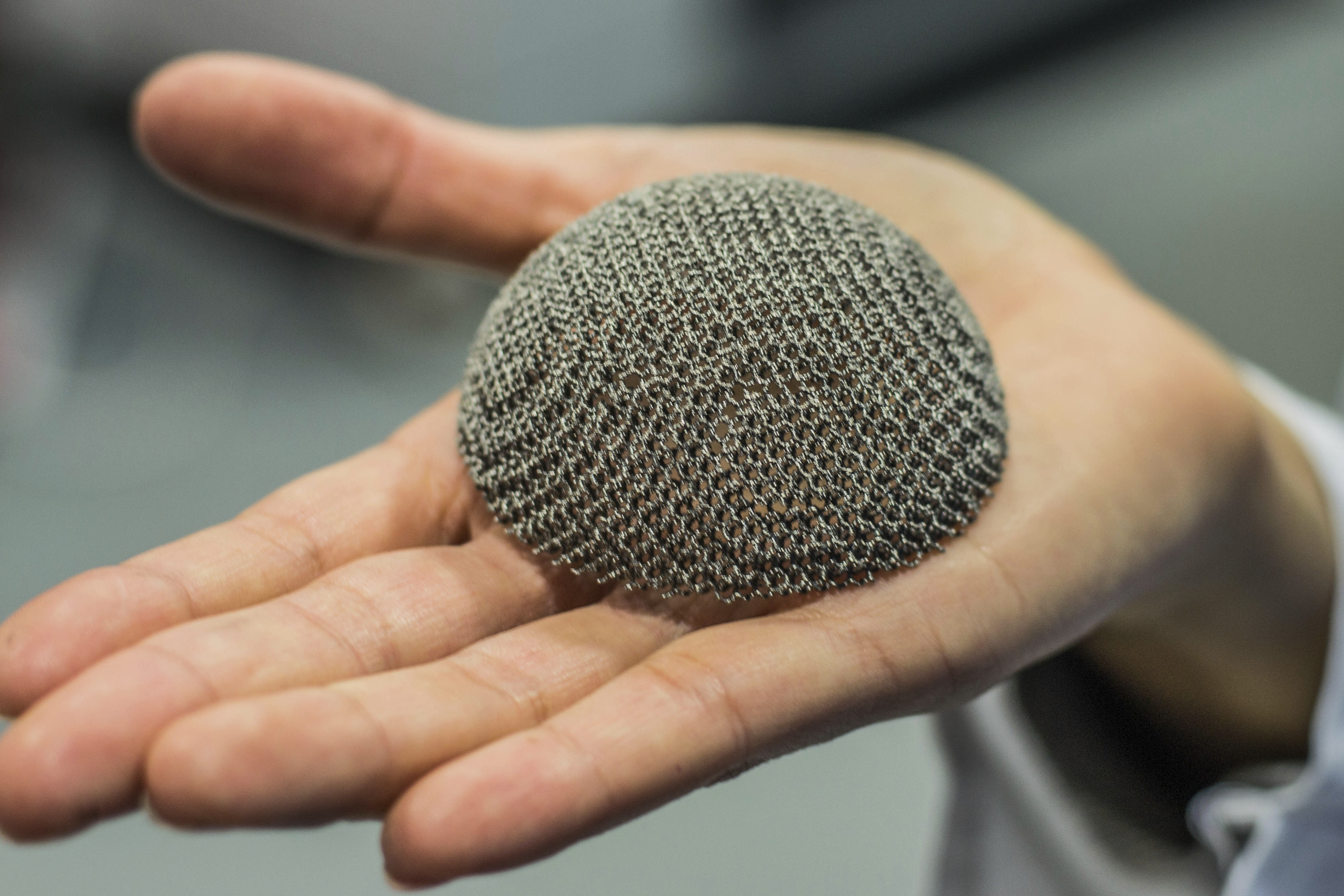

Depending on your part geometry, we can create prototype parts rapidly in a variety of alloys. Investment Casting is ideal for creating complex geometries. The process starts with the creation of a wax pattern, which is ultimately burned out with liquid alloy. As-cast tolerances fall within .007” – 040” and the finished part can be machined or EDM’d to achieve tighter tolerances. Materials include Aluminum, Zinc, Magnesium, Steel, and Ti-6AI-4V.Plaster Casting is best utilized when the part geometry has been designed for production die casting and when the volumes are sub 200. The process includes the creation of a machined or SLA master pattern which ultimately becomes a disposable cost-effective plaster tool into which the alloy is gravity poured. The process is perfect for prototypes or short-run production. The tools can be quickly and cheaply modified. Achievable tolerances range from .015” to .045”. Materials include aluminum, magnesium and zinc.

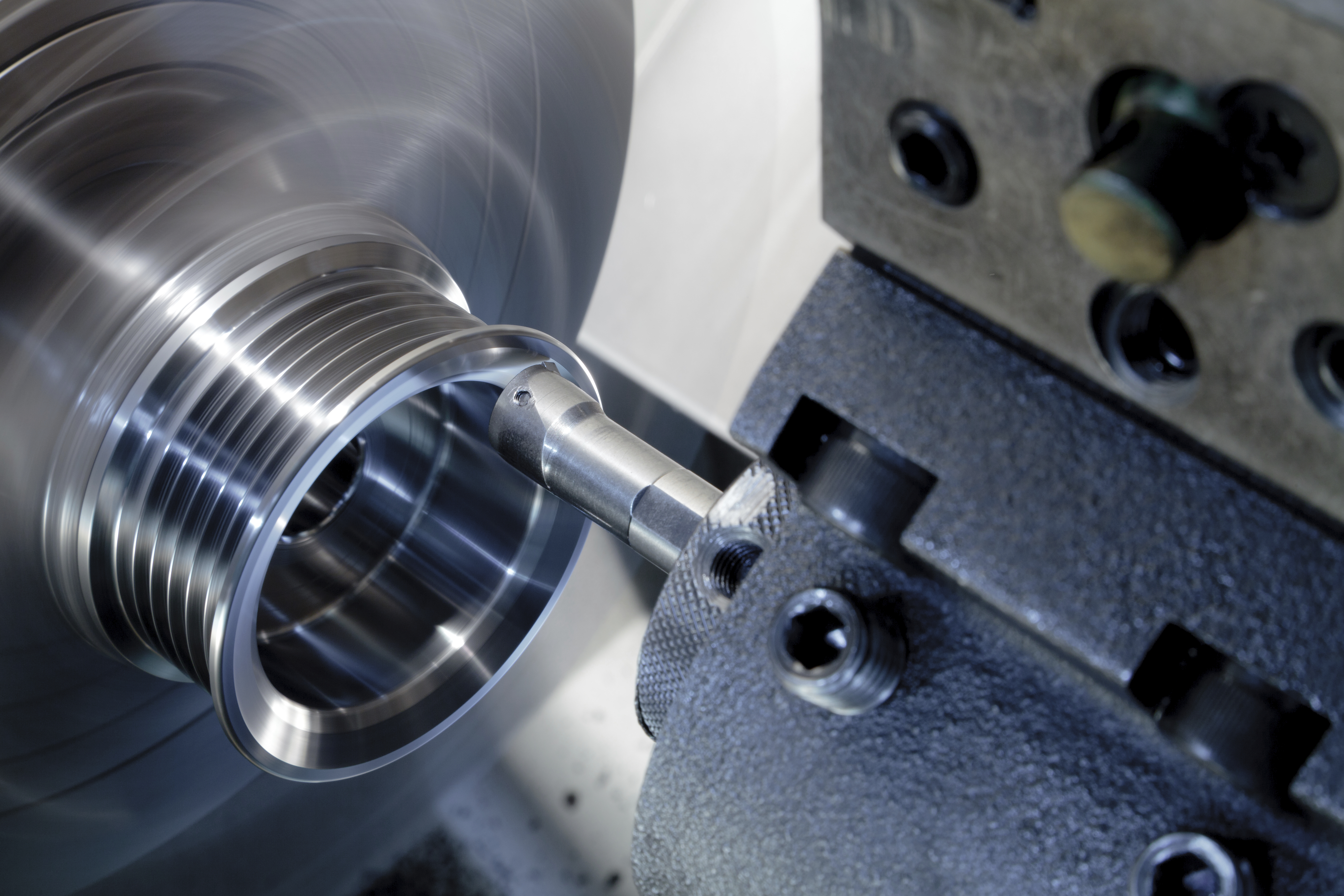

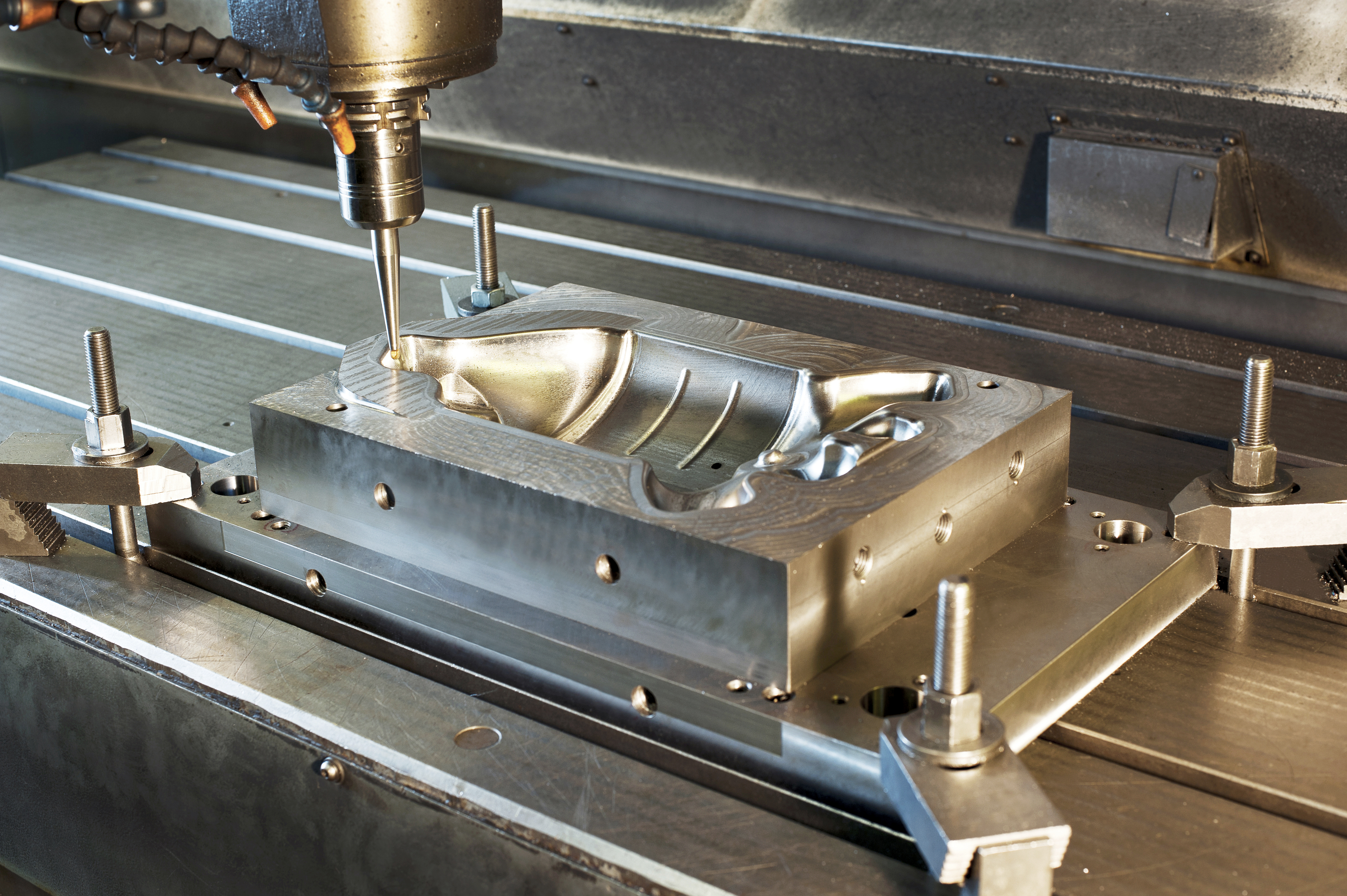

When finished, parts from either process can be machined, EDM’d, painted, polished, powder coated, sand blasted, chem film and more.