What Is An STL File?

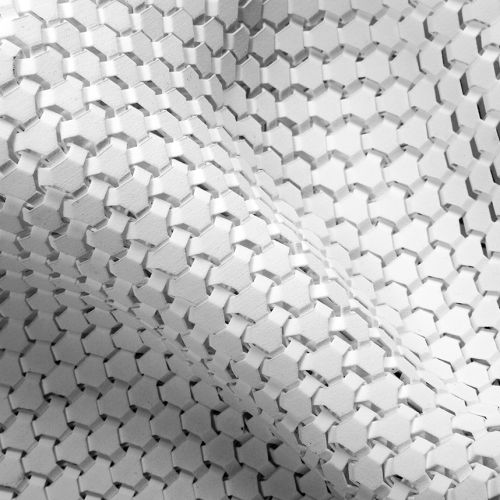

The simple answer to, “What is an STL file” is that it’s the most commonly used format in additive manufacturing for 3D printing. What STL stands for depends to a point on who is giving the definition. It can be interpreted as Stereolithography, Standard Triangle Language, or Standard Tessellation Language. However, who calls it what is less important than what you can do with a 3D printer STL file. Information Storage The STL file is used as a storage point for information concerning a 3D model. The information is stored in a format that offers a representation of the “raw” surface of your model in tiny triangles. The more detailed and complex your 3D model is, the more triangles the program will use to create a representation of the model. What makes the 3D printed STL file so useful that the vast majority of shops with 3D printers use it? How Is an STL File Created? Now that you have the basic answer to “What is an STL file,” let’s dig a little deeper and see how it’s made. Every 3D printing project starts with an idea followed by a model. Once you have developed and built your model, the next step in the additive manufacturing process is to translate your model into the right language for your 3D printer to understand. The information stored in this file format does nothing more than describe the geometry of your model. It does not contain any information on the type of material to use, texture, or color the model. But what it does have is highly detailed information about the surface or your model, which is exactly what the 3D printer is going to print once the file is uploaded. How Does This Process Work? Now that we have answered the question “What is an STL file,” it’s time to talk a little bit about how this type of software works. You already know that STL files store a computer-generated translation of your 3D item. But, what does this really mean in lay terms? It means the file encodes the entire surface geometry of your model in a process called tessellation. Tessellation is a process in which the surface of your model is covered in geometric shapes, most commonly triangles. The information for the geometric shapes is stored in the file until needed for the production run. 3D Printing from an STL File The process of additive manufacturing involves adding the production material one layer at a time or by sintering. Sintering metal involves adding powdered metal layer by layer. A 3D slicing tool will take your model and turn the various layers into a 2D image. This image is then placed in the GCode file. GCode is the language used by 3D printers to create the final product. The Standard Tessellation File is considered to be a universal language that virtually all 3D printers can read. One vital issue you should be aware of is that if your file is damaged in any way, the 3D printer won’t be able to print it. And, lastly, STL files can be created from STP files so it’s always best to send over a STP file and allow us to turn it into an STL file. At Additive Manufacturing, we use the latest technology and software, including the STL file, in our 3D printing process to ensure we deliver perfection every time. For more information, you can reach us at (877) 238-7907.