What Changes has the CNC Mill Lathe Made in Manufacturing?

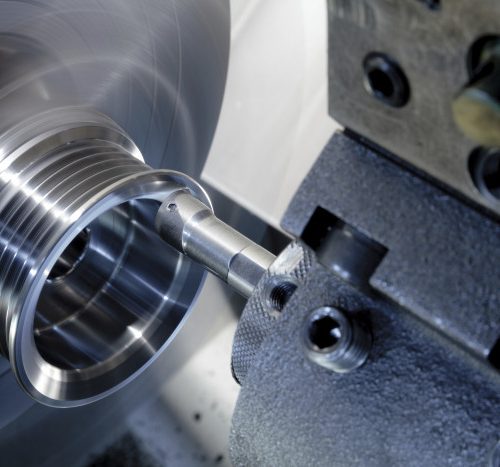

CNC or computerized numerical control is a form of machining that has been around for over 80 years. Today, thanks to advances in technology, combining a CNC machine with CAD (computer-aided design), high-speed automation, and modern production capabilities, CNC machining is now considered a fully integrated form of manufacturing technology. In fact, this type of machining now plays a major role in the development of new technologies. Companies like Additive Manufacturing, LLC have made the switch from old school technologies to CAD and CNC machines. The Old Ways Prior to the development of the CNC mill / lathe, companies like Additive Manufacturing, LLC required multiple operators to run their drill presses, lathes, mills, and routers. Each operator had to read and interpret the engineer’s drawings and then figure out the best way to add the required features to the parts they were working on. The more complex the part, the more frequently the part might have to be reoriented and remounted by hand. This was a very time-consuming process for both the design engineers and the machinists, slowing down the manufacturing process. The Dawn of CAD Today the 3D CAD drawing files are fed directly to the CNC mill lathe where the computer reads the file and plans the entire machining process. Along with this, the engineering design includes certain dimensional dependencies that are used to maintain critical dimensions and tolerances. The new computer-controlled CNC machines use articulating tables that make it possible to reorient both tools and parts without ever having to remove and relocate the parts by hand. Today, operators no longer have to manually operate the CNC machine, they simply program it to read and interpret the CAD files, which results in faster production with better accuracy. Repetition Parts manufacturing in a factory or machine shop setting is all about repetition. The idea is to be able to make replicas of the original part faster, with more accuracy, and in large quantities. The advent of CNC machining has helped make major advances in both precision and accuracy. With operators no longer required to remove and remount the parts, but instead being able to rely on a CAD file, and computerized CNC lathe, far fewer errors are likely to occur. The accuracy of the machine has a direct impact on the quality of the finished part. The more consistently the parts are mounted at the outset, the more accurate each part in the production run is likely to be. CNC Mill / Lathe Machines Offer Scalability Many CNC milling machines are capable of completing more than one operation at a time, in comparison to manual machines that had to be reset for each operation. On top of this, modern CNC machinery is capable of running continuously for up to 24 hours a day. Given the accuracy of the finished product and the speed at which they can be produced, it is possible to turn out more parts in less time and with far more consistency. At Additive Manufacturing, LLC, we use the latest in CAD/CNC technology to ensure we can meet your specifications, required quality, and production capacity. For more information or to place an order call us at (877) 238-7907