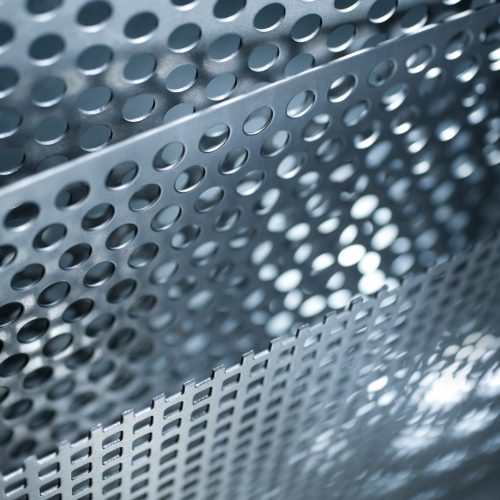

Sheet Metal Fundamentals – The Parts Start Here

Making parts from sheet metal allows for rapid turnaround times even for more advanced products. Sheet metal has a virtually unlimited number of uses. It is also very durable and cost effective to manufacture with. However, it is important to know which type of sheet metal will be the best choice for your next project. The experts at Additive Manufacturing look at the five most common types of sheet metal and their applications. Hot Rolled Steel Hot rolled steel is the perfect choice for many projects that require a cost-effective flat sheet of steel. However, hot rolled steel is not a good choice for any project where appearance is important. Parts made from sheet metal such as this start out with a series of rollers heated to a temperature of approximately 1400° Fahrenheit. Hot rolled steel is easy to shape and form and is one of the more economical materials that can be used for parts manufacture because large quantities can be manufactured quickly. Hot rolled steel often has surface imperfections that limit where it can be used. Cold Rolled Steel This type of sheet metal manufacturing involves a similar process to that used in the manufacture of hot rolled steel. However, during this time, the steel is washed using acid and then heat treated. This process means that when you manufacture parts from sheet metal such as this, they have a smooth finish. Worth noting is that this type of sheet metal is more durable than its hot-rolled cousin. Mild Steel Mild steel is manufactured using the cold rolling method, but the mixture has less carbon in it. Due to the chemical composition of mild steel, it is excellent for use in applications where welding is to be used. One of the most common uses of mild steel is in the automobile industry where many body parts can be press-formed quickly and accurately. Copper One of the most common uses for copper, after the sheet metal manufacturing process is complete, is for jewelry. Copper can be easily bent and pressed into a number of different shapes. It’s also highly conductive, making it a very popular choice for use in the electronics and electrical industries. Aluminum Aluminum sheet metal is very malleable (meaning it can be easily bent and shaped) and is also very resistant to corrosion. Along with being a popular choice in the jewelry world, aluminum sheet metal is used for a wide variety of appliances and in various electronics industries. Aluminum does have the advantage of being highly resistant to corrosion. No matter whether you choose steel, copper, aluminum, or a blend of different metals, when it comes to sheet metal manufacturing, you need access to a supply of sheet metal that is consistent and of superior quality. If you need help choosing the right sheet metal for your next product, call the pros at Additive Manufacturing at (77) 238-7907